My first attempt at embossing definitely didn't go as planned and has left me quite disheartened. I think why it went not as planned is because of lack of knowledge and taking approach that wasn't appropriate for what I needed to do.

Initially I had a laser cut session to cut my templates out of mdf as I thought that this would be the appropriate material to use. This part of the process went smoothly and my pieces were cut successfully.

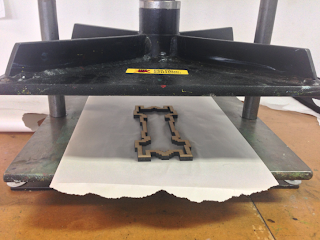

After my templates were completed I took them to the print room to start the embossing. When I arrived and asked for help I was told that the items I had weren't ideal but there was still something I could try. I found that the better material to use would have been mount board as it was thin enough to go through the roller press whereas my wood was to thick to fit through. Because I couldn't use the proper press I used an alternative method and machinery, the clamp press.

To start the process I soaked my paper samples in water so that the embossing would take more easily and would have more of an effect. I then placed the piece in between other sheets of paper and rolled it with a rolling pin to remove the excess moisture.

Next I placed my stencil inside the press on top of a sheet of news print to give it something to push against. A piece of tissue was then placed on top so that the burn marks from the mdf would't transfer onto my designs that was put on top. I then finished with another layer of news print and a cushioned layer to take some of the pressure. I then twisted the clamp as tight as I could go to press the paper and stencil together.

Although when I removed my samples the effect was no where near as strong as I thought it would be. I tried the process a few times and the results were always as disappointing, sometimes the paper even ripped because the edges of the wood was to severe. I also think that because the paper was patterned it meant that the embossed were less visible and slightly camouflaged.

No comments:

Post a Comment